Hamstrung Dial Stringing

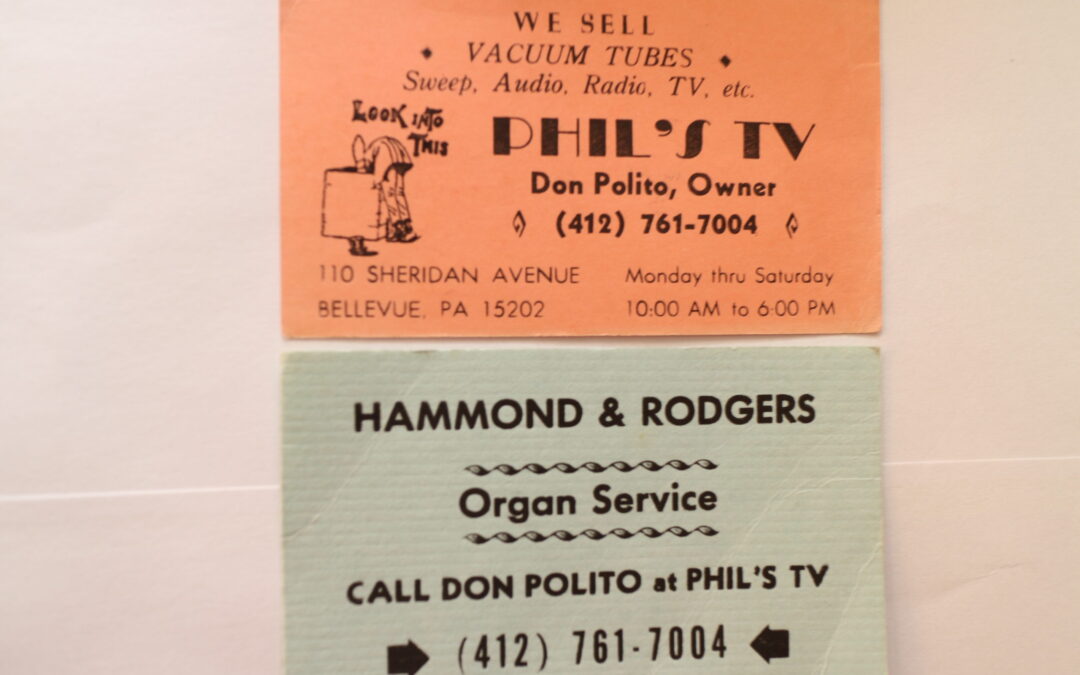

I need your help. What you’re looking at here is the Hallicrafters S-38B dial string mechanism. The “wheel” closest to you in the image is for the main dial. The one in the background is a similar mechanism for the bandspread dial. Both dial cords are broken (thanks Ron!). The string in each case has a simple path around the “wheel”, around a knob shaft, and back to a spring which pokes through a hole in the wheel. You can see the springs in the pix. To be clear, on both the main dial and the bandspread dial, there is one string that makes a loop that starts AND ENDS at that spring. I am thinking that the easiest way to re-string these is to loosely lay the string in its correct path and then tie both ends to the spring. Then finally, the other end of the spring is poked through the hole in the wheel which pulls on the spring thereby tensioning the dial string. This won’t be any picnic to do. Is there an easier way?

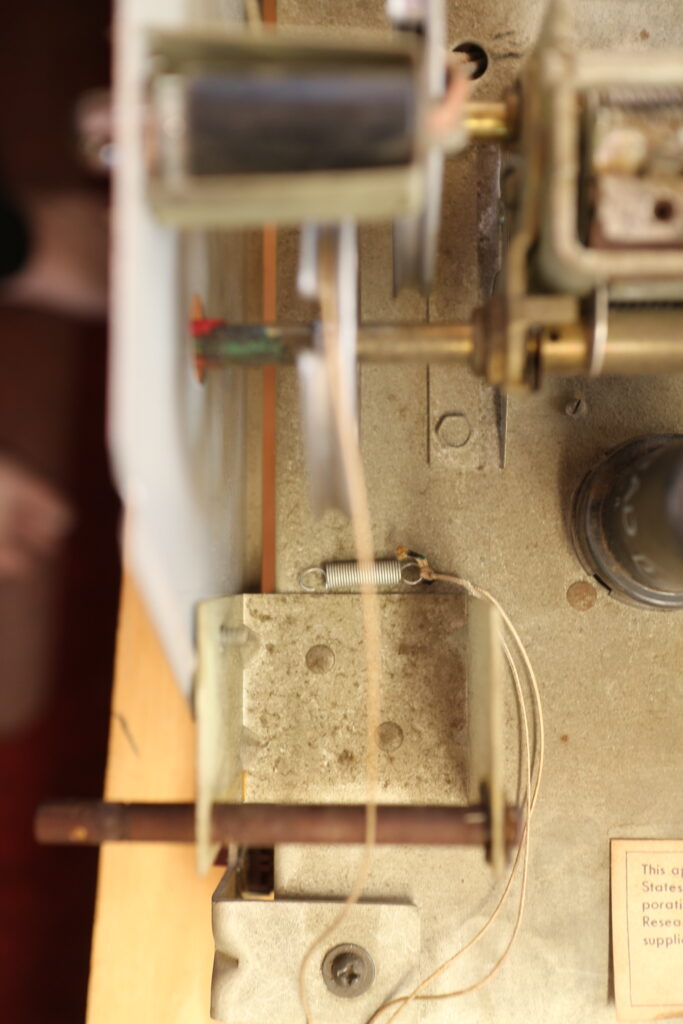

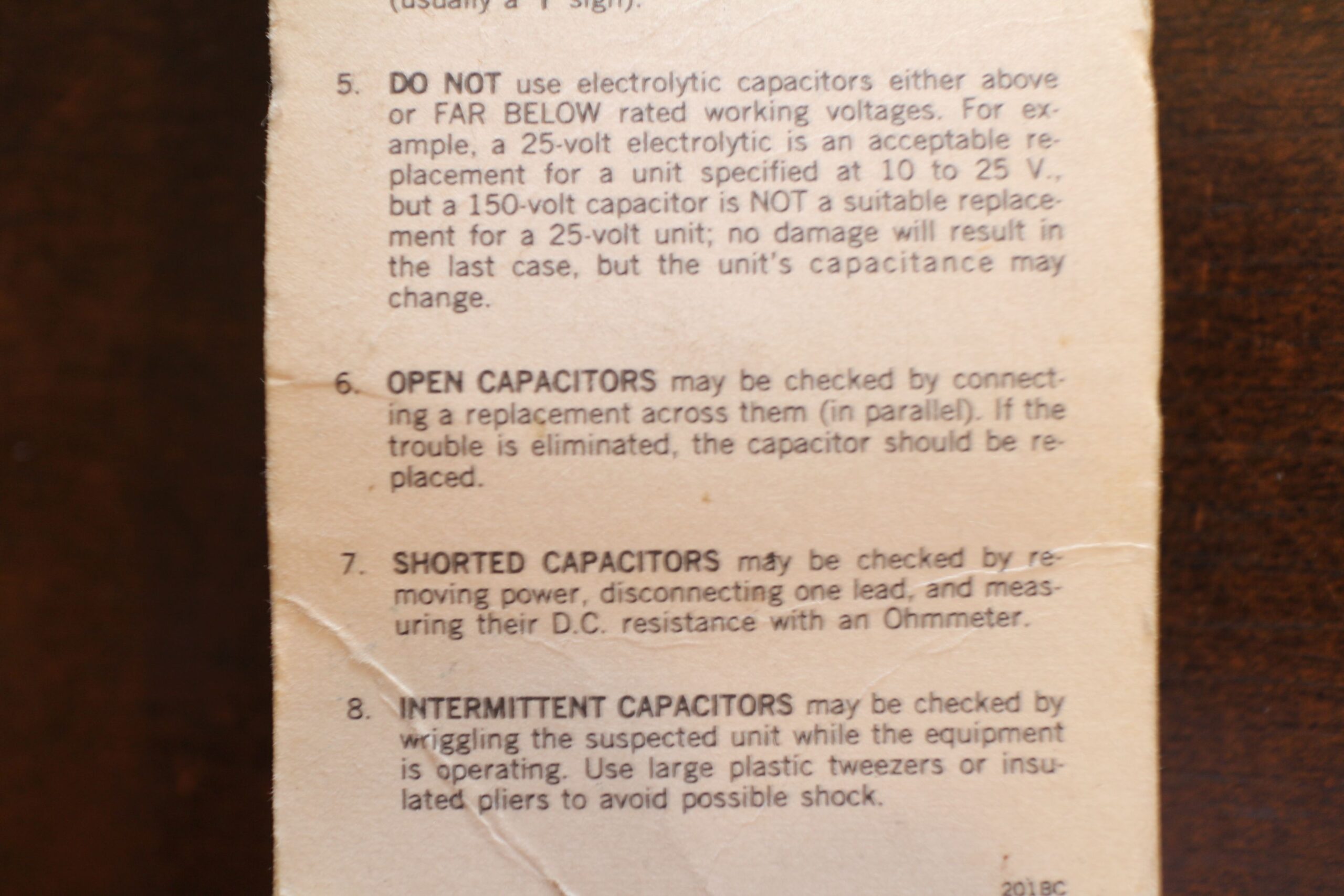

Capacitor Tips

Capacitor Tips

The pictures below are from the back of a 1970’s-vintage Calectro electrolytic capacitor package. I think it’s hard to argue with any of this. What do you think?

60/40?

Two Identical Rolls of Solder?

The pic shows two identical rolls of solder, right? Nope–trick question. There are a number of differences. But the important one (to me) is the ALLOY. Until 2 days ago, I would have said there was no difference in the alloy–60/40 or 63/37–c’mon–they are the same, right? Wrong. As some of you know, I am building a modern 3-rail train layout. I was having a devil of a time soldering leads to the track. It got to the point where I was ready to try anything. I tried a new flux. I tried more power in the iron. I tried several difference surface preps–grinding the track, wire brushing, filing, etc. Nothing worked. In desperation, I was rooting through my soldering stuff and came across this 63/37 alloy solder. In the “try anything” spirit, I applied heat, laid the solder down, removed the iron, blew on the connection to cool it, and…..doggone it if it didn’t make a perfect solder joint. Crazy. But there it is–63/37 worked with ease where 60/40 would not hold despite my best efforts. Comments? Has anyone else seen this?